During the global pandemic, the wine industry proved its versatility in finding flexible solutions. From a largely on-premise distribution model to creating more accessible e-commerce and convenience retail options, quick moving suppliers enabled the wine industry to demonstrate its resilience. However, with change now the only constant in the wine industry, how are producers continuing to adapt?

Five trends transforming the world of wine¹:

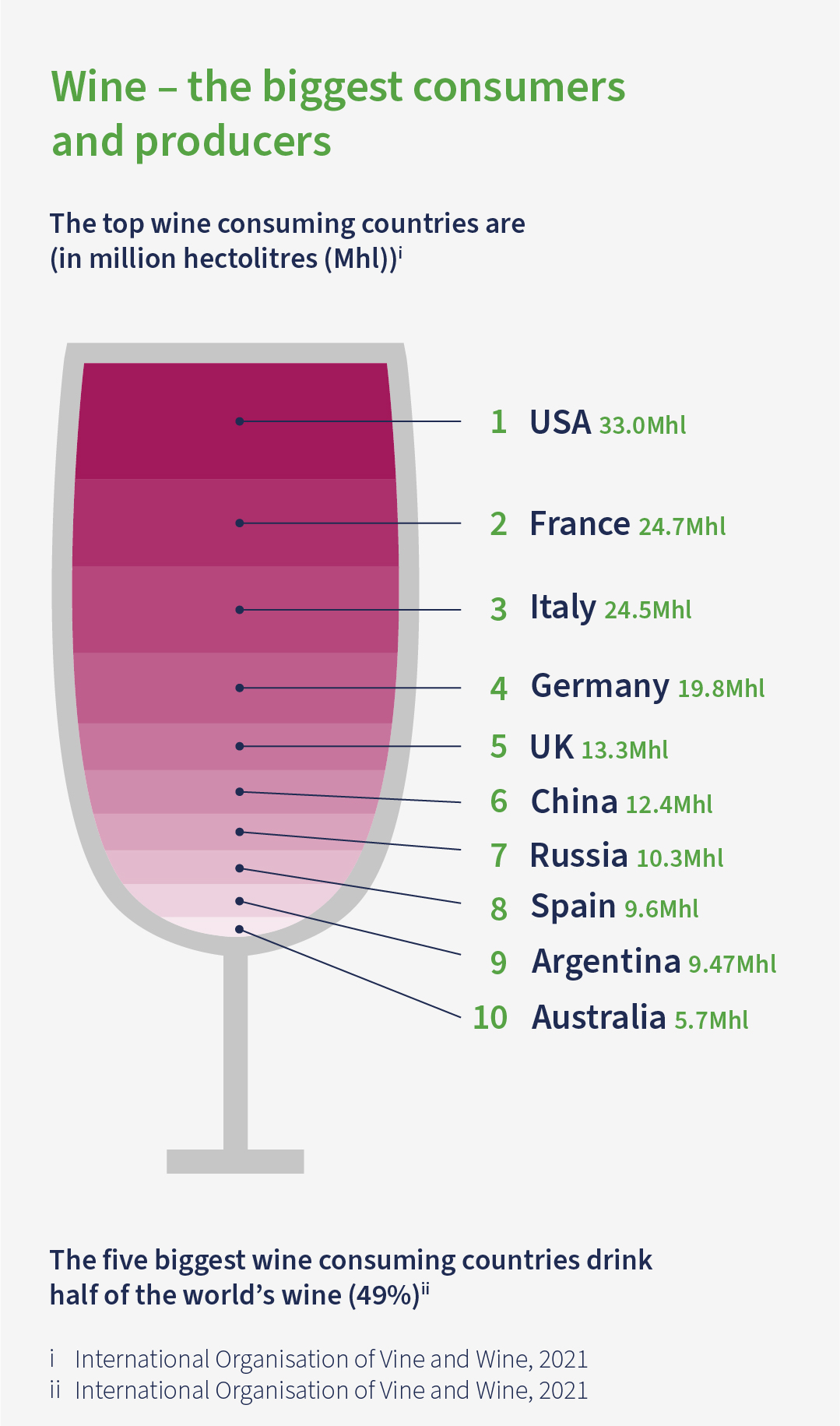

Despite the impact climate change is having on wine production that is being felt across the world, the wine industry is still predicted to grow by a CAGR of 4.28% until 2026². The fastest growing market is Asia Pacific; however, Europe is still the largest market. Key factors expected to fuel growth over the coming years are product premiumization and the demand for wine due to its health benefits. At present, the five biggest wine consuming countries drink half of the world’s wine (49%)³.

Although the wine industry is facing significant change, an area that has been slower to embrace adaptation is wine packaging. However, according to industry predictions, change is on the horizon for wine packaging and includes:

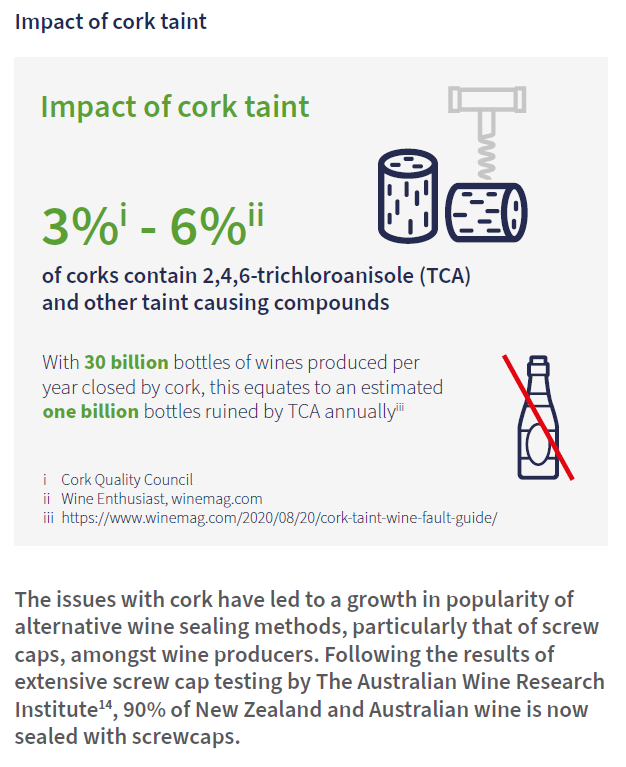

Since the earliest vintners began producing wine on a large scale in 6,000BC, the challenge has been how to store and serve this precious commodity. For many years the glass bottle and cork have seemed like a match made in heaven. However, over recent years, issues with cork taint have led to wine providers exploring other options.

The challenge of using cork:

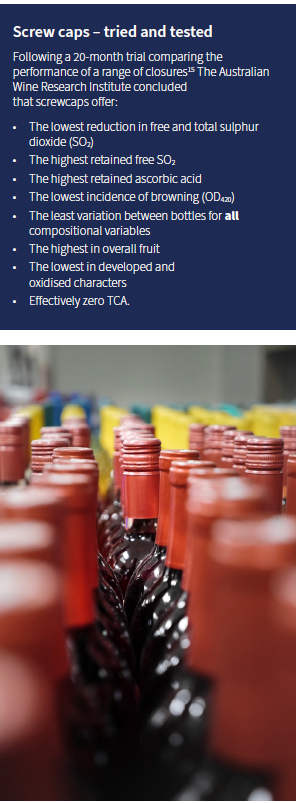

Over the years the question of maturation has been raised when it comes to screwcaps. Afterall isn’t a cork needed for the wine to breathe, to develop and to age properly? The answer to this is a simple ‘no’. “Oxygen is not the agent of normal bottle maturation16”. In fact, bottle maturation is the opposite of oxidation and it is via ‘a process of reduction or asphyxia, by which wine develops in the bottle.17” To summarise, “When a wine ages in the bottle, the oxidation – reduction potential – decreases regularly until it reaches a minimum value, depending on how well the bottle is sealed. Reactions that take place in bottled wine do not require oxygen.18”

Over the years the question of maturation has been raised when it comes to screwcaps. Afterall isn’t a cork needed for the wine to breathe, to develop and to age properly? The answer to this is a simple ‘no’. “Oxygen is not the agent of normal bottle maturation16”. In fact, bottle maturation is the opposite of oxidation and it is via ‘a process of reduction or asphyxia, by which wine develops in the bottle.17” To summarise, “When a wine ages in the bottle, the oxidation – reduction potential – decreases regularly until it reaches a minimum value, depending on how well the bottle is sealed. Reactions that take place in bottled wine do not require oxygen.18”

Screwcap closures differ greatly from cylindrical stoppers made of cork or synthetic materials in their mode of sealing. The main difference is that they seal around the rim of the bottle, rather than along the internal surface of the bottle’s neck. The screwcap is traditionally formed of a malleable aluminium alloy that is rolled onto the bottle. This is then combined with a wine liner that creates a seal between the closure and the bottle:”

Screwcaps and liners are proven wine sealing technology. Using a specialised liner, such as Selig’s oenoseal®, ensures excellent oxygen barrier performance, no negative impact on wines prone to reductive notes and a reduction and prevention of volatile sulphur compounds (VSCs)….all from a technology that is cheaper than a cork.

感谢您创建账户,我们将更加高效、快速地为您服务。

我们向您发送了一封邮件,以此来验证您的账户。