Protecting products and the environment

The pressure to reduce plastic packaging is coming from many sides and the tide is turning, as manufacturers make changes to avert the potential disaster of there being more plastics than fish in the ocean by 20501. One of the tools in the packaging reduction toolbox is ‘lightweighting’: its little-by-little approach is having a significant impact, offering food, beverage and pharmaceutical providers ways to improve their sustainability credentials in these tough economic times.

Reducing plastic impact

With less than 10% of plastic packaging at present recycled2, many companies are looking for ways to reduce the amount of plastic used in their product packaging. Lightweighting – the reduction of the overall amount of any material in a piece of packaging – has become increasingly important as part of the sustainable packaging toolbox. Alongside the choice of alternative packaging and using recycled materials, lightweighting is being used by large and small food and beverage producers alike.

This little-by-little packaging adjustment approach is proving popular. Nestle, for example, has reduced the weight of its water bottles by 22% over the last ten years and through its eco-design process has managed to avoid the use of more than 142,000 metric tons of packaging material by the end of 2019, compared to the baseline of 20153.

Promoting freshness, safety and affordability

In the EU, around 88 million tonnes of food waste is generated annually, with associated costs estimated at 143 billion euros4 and nearly 40 million tons of food is wasted in the US every year5, equating to more than $161 billion6. A significant amount of this waste is from fresh produce thrown away by households each year. Although a consumer re-education programme is needed, packaging and its ability to extend the shelf-life of foods plays a key part in the food waste reduction puzzle.

Plastic is difficult to replace in many food and drink applications, as it promotes product freshness, affordability and safety. However, the practice of lightweighting, along with improved packaging recyclability and reusability are all helping reduce the negative impact of this material on the environment.

Diageo, for example, has saved 1,200 tonnes of packaging in North America by a simple redesign of its 1.751 Smirnoff bottles. By removing the handle on the side of the bottle, 137g, or 12.6% of the total container weight, has been saved. With 8.7 million bottles being sold in this format, the reduction saves approximately the same weight as 96 London double-decker buses, or seven Boeing 747s7.

The benefits of lightweighting

The benefits of lightweighting

Lightweighting as a process delivers a range of cost and environmental benefits:

• Material and production cost reductions – less packaging means savings on the raw material and on production costs to deliver a more cost-effective overall product

• Transportation and production energy savings – lighter products equates to reduced production levels and fuel consumption for their transportation, leading to lower CO2 emissions overall

• E-commerce cost-efficiencies – as demand increases for online shopping, lighter packages are proving their worth for e-commerce.

Although lightweighting helps reduce shipping costs, has environmental benefits and is proving popular with e-commerce applications, attention needs to be paid to the quality of the packaging and the overall consumer experience it delivers. Afterall, thinner packaging can lead to performance issues.

Lightweighting and induction heat sealing

Packaging must be robust, tamper-proof and leak free if it is going to provide customer satisfaction. To achieve this, whilst still lightweighting the packaging and closures, producers have turned to a variety of methods to allow lightweighting, which can include production line changes, such as compression molding technology and packaging redesign to remove unnecessary features. Lightweighting combined with induction heat sealing has stood the test of time however, as it creates a strong, hermetic seal that has many benefits.

The benefits of induction heat sealing:

The benefits of induction heat sealing:

• Quick and economical to apply

• Provides a strong, hermetic seal

• Can show tamper-evidence on packaging if needed

• Provides leak prevention

• Can provide clean peel on packaging for recycling ease if needed

• Promotes freshness retention and improves the shelf-life of product

• Reduces spoilage levels

• Deters in-store theft

• Enhances customer confidence in the product’s integrity

• Is suitable for high-volume operations

• Can be used on a wide range of glass and plastic containers

• Reduction of food waste

How it works

Induction heat sealing uses a laminated liner which is placed inside the container closure. The essential components in the seal include an aluminium layer and a heat seal layer. The specific material of the heat seal layer is chosen on a case-by-case basis, depending on the material of the container and what it is packaging.

On the automated production line, screwing the cap onto the container brings the seal into position. The assembly then passes within the field of an electromagnetic energy, which generates an induction current – and heat – in the aluminium, without any need for contact. The heated seal adheres firmly to the rim of the container as it cools. As well as being fast, induction heat sealing is relatively inexpensive and environmentally friendly due to its low energy and material consumption, including plastics and its lightweight end results.

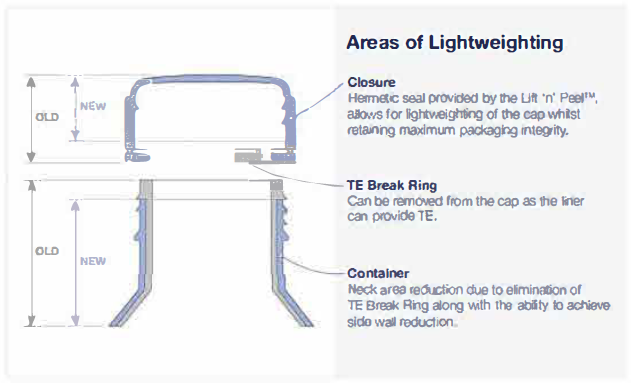

Here are some of the areas of a container that can be light-weighted thanks to induction heat sealing:

Selig – tried and tested

Selig – tried and tested

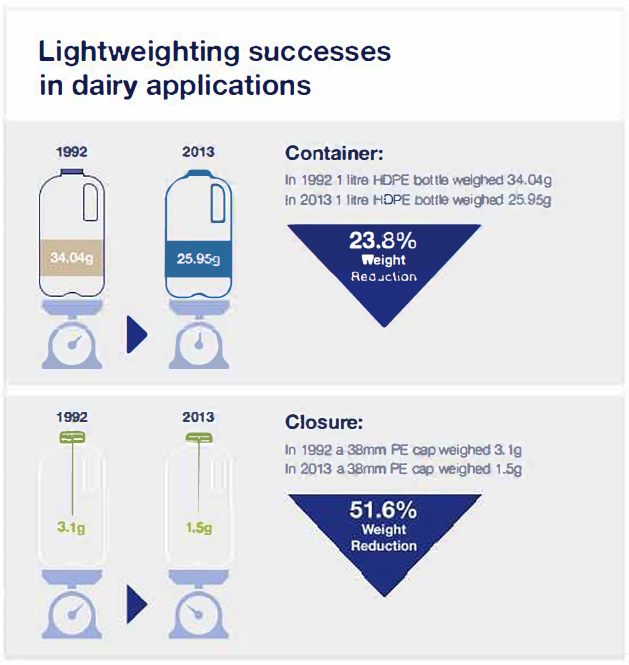

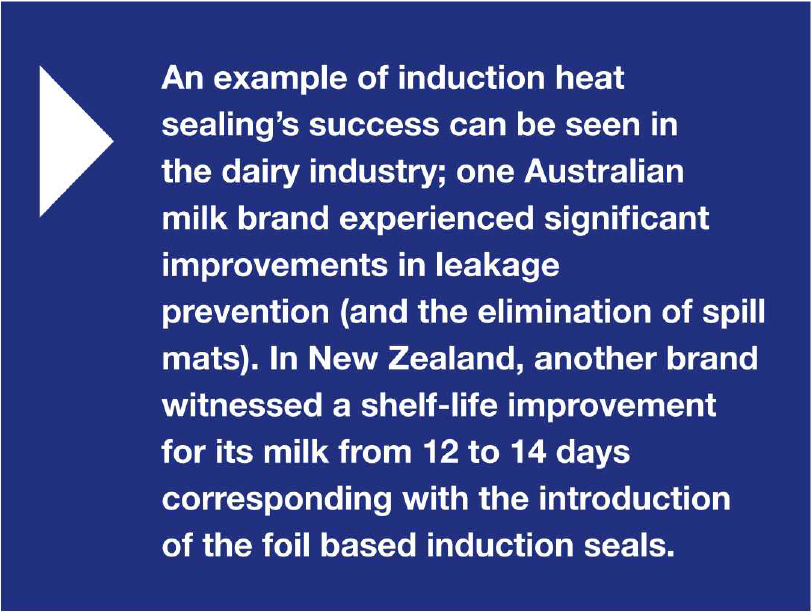

As a global leader in sealing solutions, Selig has helped many producers lightweight their product ranges. Lightweighting and induction heat sealing success can be seen across the food sector. For example, thanks to induction heat sealing, many PET ketchup bottles are now reduced in thickness. In addition their caps have been lightweighted and their tamperbands and shrinkseals removed. The impact of light-weighting and induction heat sealing on dairy packaging has also been significant:

Selig’s Lift ‘n’ Peel™ range

Selig’s Lift ‘n’ Peel™ range

Selig’s Lift ‘n’ Peel™ range of induction seals are a popular choice when lightweighting products. As well as providing a strong hermetic seal for maximum leak prevention and package integrity for both wet and dry products, the Lift ‘n’ Peel™ range features an ergonomic tab that ensures easy opening for all consumers, even those with limited dexterity. Another benefit of Lift ‘n’ Peel™ is that when removed, it leaves no residue on the bottle, making the container easier to recycle. Furthermore, they can be printed with a custom logo or design for brand differentiation and require no additional processing or equipment beyond standard induction sealing machinery to include in packaging.

Lightweighting, recyclability and sustainability

As well as lightweighting, companies are working hard to improve their overall recycling credentials too. To this end, Selig’s Expanded Polyethelene Uni-Foam™ (EPE) cap liners are 100% polyethelene, a material that is widely recycled. These liners are widely used in a range of industries, as they provide good primary and secondary seals, whilst being able to be fed into the recycling system. Selig is also researching the potential of polypropylene and polyetheylene liners that match a container’s cap, to make seal recycling even easier in the future.

As can be seen, lightweighting – combined with induction heat sealing – can achieve significant environmental, cost and functional benefits. Food, beverage and pharmaceutical providers are amongst those who have used lightweighting to make small, yet significant, changes to their packaging. So, why not see if Selig can help you increase productivity, reduce returns and lengthen product life with a little packaging lightweighting too?

As can be seen, lightweighting – combined with induction heat sealing – can achieve significant environmental, cost and functional benefits. Food, beverage and pharmaceutical providers are amongst those who have used lightweighting to make small, yet significant, changes to their packaging. So, why not see if Selig can help you increase productivity, reduce returns and lengthen product life with a little packaging lightweighting too?

感谢您创建账户,我们将更加高效、快速地为您服务。

我们向您发送了一封邮件,以此来验证您的账户。