PHT Manual

Learn the process, materials, and equipment used in induction heat sealing.

This informative manual provides closure manufacturers and CPG’s with the latest leading facts on induction sealing. It discusses types and uses of induction seals, how to correctly set an operating window, and troubleshooting examples to eliminate weak or scorched seals. Find guidance for matching the closure to the container’s neck profile for even pressure, and design recommendations for liner geometry. Learn the do’s and dont’s of setting up an induction line.

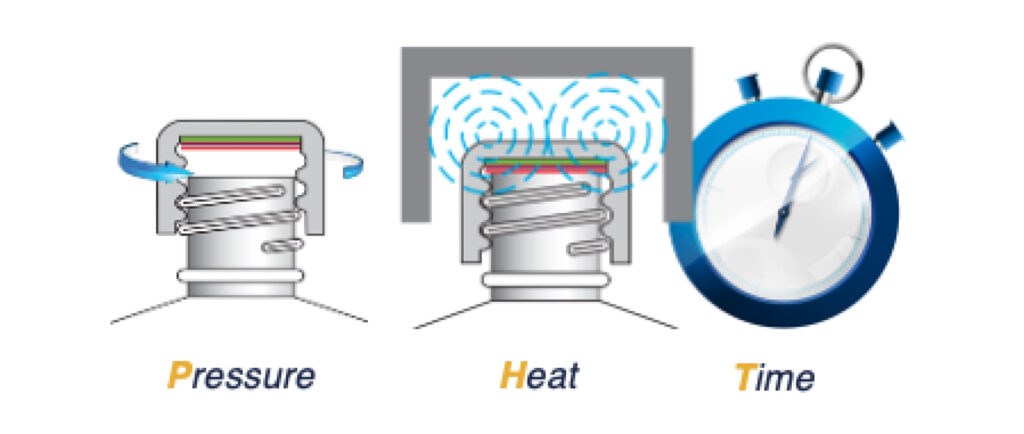

Understanding the induction process is important in choosing an induction seal. Pressure, heat and time are the variables in this process. The pressure is the pressure between the liner and the container land area which is controlled by capping equipment. The heat is what helps soften and melt the heat seal surface of the liner and is controlled largely by the power setting on the induction heating equipment. The time component refers to the time the foil is exposed to the induction heating process and is controlled by the speed of the conveyor which exposes the packages to the induction energy. Our PHT™ manual is available to registered customers on our website. It provides details of the process, setting up ideal parameters, and troubleshooting.

The design of the neck and threads of the container must be matched to the closure so that the closure will give even pressure to the land area and the skirt of the closure will not bottom out on the shoulder of the container. This is known as the ‘H’ dimension of the container and closure. If the land area of the container has any defects, such as parting line mismatch or land saddle it will create an uneven land surface and result in uneven pressure.

The distance of the induction sealing head to the foil in the liner is very important. A 3mm or 1/8″ gap between the induction foil and the coil is recommended. It is also important that the induction sealing head and conveyor are parallel to one another, as is having the right profile of the induction coil for the job, i.e. a flat or tunnel coil. There are various induction coil sizes and styles to accommodate various package designs and sizes.

Time is needed when the closure is passing under the induction coil. This is called the dwell time. The induction seal liner needs sufficient time under the coil to be heated to the correct temperature for the sealing surface to melt and bond to the land area of the container. A minimum of one-minute is needed after sealing to allow cool down, during which, the container must not be bumped, banged, roughly handled, or opened.

Thank you for creating an account and giving us the ability to serve you more effectively and quickly.

We have sent you an email so we can verify your account.