Brands have trusted Selig with their flexible packaging needs for more than 50 years. Specializing in high-end custom printing, smaller runs, and short lead times, Selig’s flexible capabilities deliver products to market faster without sacrificing quality or sustainability.

Brands have trusted Selig with their flexible packaging needs for more than 50 years. Specializing in high-end custom printing, smaller runs, and short lead times, Selig’s flexible capabilities deliver product to market faster without sacrificing quality or sustainability.

• Cheese

• Condiments

• Confectionary

• Snacks

• Spreads

• Coffee & Tea

• Dairy

• Energy & Sports Drinks

• Functional Beverages

• Baby Care

• Body Care

• Facal Skincare

• Hair Care

• Sexual Healthcare

• Sun Care

• Nutraceutical

• Over-the-Counter (OTC)

• Pharma

• Agricultural

• Institutional

• Pet Care

• Pool Care

• Surface Cleaning

• Blister Packs

• Engineered Laminates

• Hazmat Materials

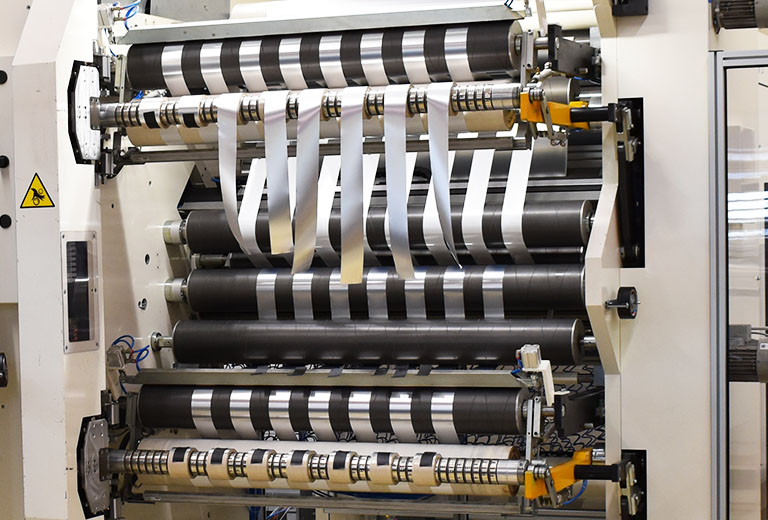

A majority of the flexible packaging we produce serves the food and beverage markets for products such as chocolates, baked goods, cheeses, dry soups and powdered beverages. This product range features high-resolution 10-color rotogravure printing, cold seal adhesive technology, as well as laminates and coatings with unique barrier properties. Brands choose Selig as their go-to partner when projects require custom printing, shorter lead times, and lower minimum order quantities.

Selig’s engineered laminates product range features highly engineered barrier laminates to protect oxygen or moisture-sensitive products, such as electronics, pharmaceuticals, and cosmetics. In cases where extreme barriers are needed, thicker laminates can be manufactured that are subsequently thermoformed. In addition to protecting sensitive products, Selig engineered laminates also protect human life. Highly engineered complex barrier laminations for military and industrial applications such as industrial PPE (gas masks & hazard suits) and military NBC protection (Nuclear, Biological & Chemical) are designed, lab-tested, and manufactured in Niederglatt, Switzerland.

Selig has supplied and manufactured flexible materials since 1937 and has served some of the most renowned brands in both food and non-food applications. Our flexible packaging not only protects products from tampering or degradation but also promotes our customers’ brands with high-quality printing.

Selig’s Eco-Flex range of flexible materials ensure maximum recycling efficiency. Our solutions include six options that are polypropylene (PP) recycling stream compatible. We also offer cellulose-based material that is not subject to standard plastic regulations and is considered a renewable and biodegradable material.

Selig provides custom solutions for wrappers in both multilaminate and monolaminate structures for the food industry. Our expertise in monolayer napolitaines as well as paper-based, perforated structures for cheeses are preferred by brands.

From gas masks to hoods to tents, Selig’s protective laminates are designed to protect people from harmful chemical or biological environments. These defense laminates undergo rigorous testing and are commonly used in military or industrial situations.

Thank you for creating an account and giving us the ability to serve you more effectively and quickly.

We have sent you an email so we can verify your account.