Packaging and the Needs of an Ageing Global Population

A United Nations report published back in 2002 remarked that global population ageing is “unprecedented and without parallel in human history”, and that the twenty-first century will witness even more rapid ageing than the previous century. Population ageing is pervasive, and it is a global phenomenon affecting every man, woman and child.

Europe, for example, is home to a growing proportion of people who are living considerably longer than ever before. The median age has risen by more than eight years in the last half a century, jumping from 31.5 in 1960 to 39.8 in 2010, and predictions suggest this figure will climb by a further 7.4 years, to 47.2, by 2060. Moreover, the percentage of Europeans aged 65 and over is projected to rise to 29.3 per cent by 2060 from 16.0 per cent in 2010, while the number of residents over the age of 80 is expected to increase sharply to 11.5 per cent by 2060 from just 4.1 per cent in 2010.

Europe, for example, is home to a growing proportion of people who are living considerably longer than ever before. The median age has risen by more than eight years in the last half a century, jumping from 31.5 in 1960 to 39.8 in 2010, and predictions suggest this figure will climb by a further 7.4 years, to 47.2, by 2060. Moreover, the percentage of Europeans aged 65 and over is projected to rise to 29.3 per cent by 2060 from 16.0 per cent in 2010, while the number of residents over the age of 80 is expected to increase sharply to 11.5 per cent by 2060 from just 4.1 per cent in 2010.

While the pace of change of population age distribution differs greatly across continents, population ageing is inexorable and will eventually affect every part of the globe. Moreover, the phenomenon is irreversible, according to the UN report. Population ageing is enduring; we will not return to the young populations that our ancestors knew and this will have profound implications for many facets of human life.

The European Commission has admitted this demographic transition is likely to be one of the biggest challenges that the continent of Europe will face in the coming years. The impact is expected to be felt by governments, societies, national economies and businesses as Europe struggles to adapt to its transforming structure. Every industry is likely to experience profound consequences, and the packaging sector is no exception.

Product type, properties and characteristics often determine the nature of the packaging, and where container closures are concerned, this may involve the use of certain features that will prevent even a determined child from opening the package. But such features can cause problems and frustration for older users. Achieving user-friendly packaging also goes beyond the methods used to open and close it; ergonomic styling for easy handling plays a role too, and clearly labelled instructions for opening in as large a font as possible are vital, though visually impaired users will experience problems here and it may be expedient to include instructions in Braille if practicable.

In a survey, UK based research company Which? found that two thirds of people get frustrated – or suffer “wrap rage” – when trying to get into everyday packaging, whilst a staggering four in ten people said they have hurt themselves while trying to open something. A quarter of those surveyed also said they regularly need help to open packaging, which is perhaps especially worrying as a substantial number of older people live alone with little help immediately available to them.

As well as having a huge negative impact on elderly consumers, producers and retailers alike should be aware that difficult-to-open packaging can affect purchasing decisions for many products and could, ultimately, cost businesses dearly in lost customer goodwill and revenue.

As well as having a huge negative impact on elderly consumers, producers and retailers alike should be aware that difficult-to-open packaging can affect purchasing decisions for many products and could, ultimately, cost businesses dearly in lost customer goodwill and revenue.

The biggest challenge facing the packaging industry lies in creating packaging that strikes a balance between adequate consumer protection in the form of tamper evidence and ease of opening. A container needs to be secure and hermetically sealed to safeguard the integrity of its contents, yet this objective cannot compromise the practicality of the packaging and make it difficult to open for elderly consumers who lack strength or suffer from dexterity or mobility impairments.

The US FDA was among the first to issue a regulatory requirement for tamper-evident packaging following an incident of malicious tampering involving a pharmaceutical product which resulted in a number of deaths. Those regulations require one or more barriers that provide a visual indication of packaging integrity, together with appropriate labelling to allow the consumer to confirm, prior to use, that the packaging has not been compromised. And to reduce the chance of tamper-indicators being fraudulently reinstated after breach, they should carry an identifying characteristic like a distinctive pattern, logo or product name. Tamper evidence, almost by definition, seeks to make packaging difficult to breach, which raises a number of issues for the elderly and those with limited strength or dexterity who, in the absence of a more able assistant, may risk harming themselves when resorting to the use of a kitchen utensil to open a tamper evident package. Clearly, a balance needs to be struck between providing visible tamper evidence and making the package closure easy to remove – albeit with the fingers and not a paring knife!

Manufacturers have the choice of several different strategies to include tamper-evident features on primary and secondary packaging. They include shrink wrap films, bands or wrappers; boxes with tamper-evident security seals and breakable caps. Again, these may require some dexterity and more than a modicum of strength to break them open. One of the most commonly used is the tamper-proof peelable seal, yet even these have issues for the elderly.

Seals that are tough to peel off or that fail clearly to mark the point from where the seal should be lifted, are highlighted as particular problems among consumers with dexterity issues and visual impairments. With so many vital products featuring this type of seal, it is essential that packaging companies continually develop products to ensure they provide enough protection for the goods while keeping the container accessible for the consumer.

Seals that are tough to peel off or that fail clearly to mark the point from where the seal should be lifted, are highlighted as particular problems among consumers with dexterity issues and visual impairments. With so many vital products featuring this type of seal, it is essential that packaging companies continually develop products to ensure they provide enough protection for the goods while keeping the container accessible for the consumer.

One tamper-evident peelable seal technology that overcomes these limitations is induction cap sealing, an approach that uses a multi-layer laminated liner with an aluminium foil that is bonded to the container rim by means of electromagnetic induction heating. Induction liners are highly engineered laminated structures comprising a heat seal layer, chosen to match the material of the underlying container, and a layer of aluminium foil that is heated by electromagnetic induction prior to bonding.

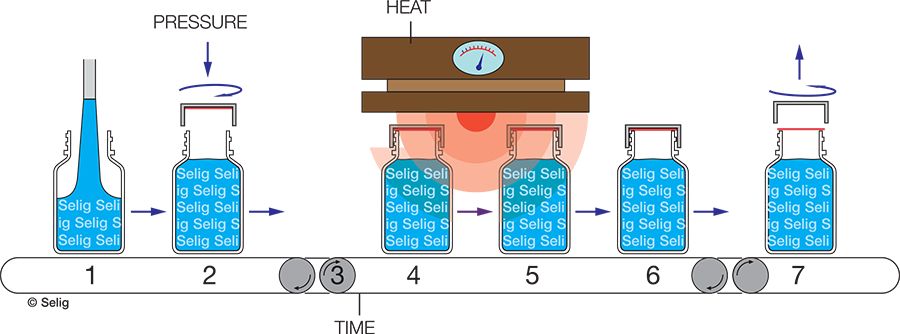

Optimum results for these seals are achieved by making an appropriate choice of lining material and using the correct measure of pressure, heat and time during the induction sealing process. Pressure is needed for the liner to have an even seal to the container rim and this is achieved by the torque heads of the capper when placing the closure onto the filled container. Heat is applied via a magnetic induction process, which raises the temperature of the seal’s metallic foil liner by means of eddy currents. Timing is crucial for a successful seal. Timing intervals include the period the closure passes beneath the induction coil and the following cooling period, during which the container must not be subject to any rough handling as it is moved by the conveyor.

Too much pressure – or cap-on torque – between the liner and bottle neck finish, excessive heat to activate the liner seal surface, or extended dwell time under the induction coil will leave users with a seal that cannot be removed with ease, while too low a level of heat, pressure or time will result in leaks or the ingress of contaminants.

Optimal operating window settings for these parameters can be determined by running a trial on the production line under typical conditions. Start by setting the induction unit to approximately 25 per cent power output and run a series of containers, gradually increasing the power output by 5 per cent each time until the desired result is produced.

Closure application torque will also need to be adjusted during trials to determine which level will provide a balance between achieving an adequate seal and easiest opening for the consumer. Ensure the power output and torque settings are marked on each container so the operating window can easily be identified during inspection following cooling, and repeated for future processes.

The choice of liner is also critical to ensuring easy-open packaging and reputable liner manufacturers are constantly developing products to match consumer needs. While there are literally hundreds of different specialist liners available to meet all manner of applications, those liners with an easy-to-grip tab, such as Selig’s widely used Lift ‘n’ PeelTM induction seals, are an ideal choice across a wide range of packaging applications.

This type of easy-open 1/2 moon tab is designed to be ergonomic, flexible and extremely strong, and is engineered specifically to maintain product quality whilst being easy for the consumer to peel. In addition, they can be printed with a customer specific design or branding logo, as well as clear opening instructions on the liner itself, indicating the position of lift and direction of peel.

An ageing global population is here to stay and the packaging sector must ensure its products constantly evolve to accommodate the needs of the elderly and remain relevant by removing restrictive design. Peelable seals are very much a part of this process, and by selecting the most appropriate lining material and optimising the induction heat sealing process, it is possible to remove the barriers that sub-par packaging can create to ensure it is easy to open while also being totally secure for a positive user experience.

Thank you for creating an account and giving us the ability to serve you more effectively and quickly.

We have sent you an email so we can verify your account.