The first domestic delivery of milk in a porcelain stoppered glass bottle was made by the UK’s Express Dairy Company in 1880. As a glass bottle is a reusable container, efforts were made to improve the bottle closure and the porcelain stopper (later glass) was replaced around the beginning of the 20th century by a US patented, disposable waxed cardboard capseal, making the whole process of sterilization and filling faster and more economical.

The first domestic delivery of milk in a porcelain stoppered glass bottle was made by the UK’s Express Dairy Company in 1880. As a glass bottle is a reusable container, efforts were made to improve the bottle closure and the porcelain stopper (later glass) was replaced around the beginning of the 20th century by a US patented, disposable waxed cardboard capseal, making the whole process of sterilization and filling faster and more economical.

Glass bottles (later sealed around the lip with crimped aluminium foil discs) continued to dominate as the UK’s preferred milk container well into the 1970s. By 2012, however, just 4 percent of milk retailed in the UK was available in glass bottles, having given way firstly to lightweight, safer and easier-to-manufacture LDPE coated cardboard cartons and, later, to the now ubiquitous screw-capped HDPE container. Since 1992 these screw capped HDPE containers have had the additional benefits of an induction sealed liner offering tamper-evidence and virtually leak-free performance.

These packaging trends are also reflected to some extent in the way milk has been delivered over the years to customers in North America. In the United States, for example, glass was phased out more rapidly than in the UK, as alternatives such as coated cardboard cartons and square HDPE gallon milk jugs proved more popular than glass containers.

As US customers were becoming accustomed to coated cardboard and plastic jugs, drawbacks became apparent at an early stage in their adoption – particularly with regards to jugs, which had no secondary sealing between the container lip and the screw cap resulting in product leakage. The remedy – which many US retailers continue to use to this day – was to accept the fact that ‘leakers’ were an inevitability and simply accept the constant task of keeping shelves clean and accepting the complaints of consumers who, on returning home, had discovered that product had leaked in transit. Indeed, a new market was spawned for ‘spill mats’ which retailers use to soak up leakages from shelf surfaces. As retailers quickly discovered, these have proved to be an unhygienic and costly inconvenience.

As US customers were becoming accustomed to coated cardboard and plastic jugs, drawbacks became apparent at an early stage in their adoption – particularly with regards to jugs, which had no secondary sealing between the container lip and the screw cap resulting in product leakage. The remedy – which many US retailers continue to use to this day – was to accept the fact that ‘leakers’ were an inevitability and simply accept the constant task of keeping shelves clean and accepting the complaints of consumers who, on returning home, had discovered that product had leaked in transit. Indeed, a new market was spawned for ‘spill mats’ which retailers use to soak up leakages from shelf surfaces. As retailers quickly discovered, these have proved to be an unhygienic and costly inconvenience.

Australian retailers were having similar experiences but growing consumer concern for better product safety, hygiene and the elimination of product leakage is seeing much wider adoption of induction seals. Selig, a global supplier of such packaging technology, who examined the market closely in that country, reports that in 2007 the introduction of its Lift ‘n’ Peel™ induction liner by the Australian dairy industry had directly resulted in a significant sales growth for the brands that adopted the Lift ‘n’ Peel™ seal. Furthermore, independent consumer research done in North America on packaged goods revealed that the vast majority (74%) of respondents would switch brands to one that made use of Selig’s half-moon lift-tab seal.

One particular Australian milk brand – an early adopter of induction sealed liners – reported in 2006 that it had experienced massive improvements in leakage prevention (and the elimination of spill mats), a corresponding growth in sales and a shelf-life improvement for its milk from 12 to 14 days.

Canadian experience is also seeing a trend towards induction heat sealing of milk containers. In June, 2017 the Royal Canadian Mounted Police were called to investigate milk recalls in British Columbia when a “potential presence of harmful extraneous material” was reported in unsealed milk jugs from a particular supplier. Health Canada said there had been no reported illnesses associated with the consumption of these products, but did conduct a food safety investigation. As this investigation continues, the dairy in question has taken the precaution of applying Selig’s tamper-evident induction sealed liners to all of its milk jugs, in addition to voluntarily recalling the packages from the marketplace that were in question.

Meanwhile, in the US, the promotion of induction sealed milk containers continues. In 2016, Selig conducted extensive focus group surveys among US consumers of dairy and other packaged foodstuffs in order to gain insights into customer preferences as well as awareness of, and interaction with, more effective sealing technologies such as Selig’s Lift ‘n’ Peel™. The results were very conclusive. Of prime importance to focus group participants were (in order of importance): ensuring product safety by providing tamper-evidence; preventing product leakage and maintaining freshness – all of which were perceived by the focus groups to be met by Selig’s Lift ‘n’ Peel™ induction seals. In addition, participants appreciated the ease of opening provided by Lift ‘n’ Peel™ and the fact that they did not require the aid of a kitchen utensil to release the seal. When asked for their preferences regarding choosing between a ‘traditional’ liner, a Lift ‘n’ Peel™ liner, or a package sealed only with a screw on cap, the overwhelming number of participants preferred a Lift ‘n’ Peel™ sealed package.

In a recent Mintel survey (June 2017) of US packaging trends, Food & Drink Senior Analyst, John Owen commented: “An increasing percentage of product launches are based primarily on new packaging as packaging continues to become more important in the food marketing mix. Not only does packaging play a central role in communicating key benefits and features, it can also help to shape a consumer’s experience with the product, and play a role in the prevention of food waste.”

Today, almost all milk is supplied to the UK retail market in HDPE screw-capped jugs, in combination with induction sealed foil seals; UK producers, retailers and consumers alike can be confident that their dairy product packaging is guaranteed to be leak-free, safe and easy to open.

Reaching this level of market saturation has not, however, been without its challenges. On the one hand, the producer wants a seal that is reliable, tamper-proof and quick to apply on a fast-moving production line, while on the other, the consumer – also seeking a reliable seal that maintains product freshness – is more concerned that the seal can be removed easily from the container.

At Selig, we have been extremely successful in addressing these issues and are now a key supplier to the UK dairy industry. Our innovative, award-winning Lift ‘n’ Peel™ easy- open induction heat seal liner provides immediate evidence of tampering. The seal’s integral easy open, half-moon pull tab has been designed to be ergonomically easy to grip, while remaining flexible and extremely strong.

While Lift ‘n’ Peel™ offers important advantages, the process of applying the liner to the container in order to achieve the desired hermetic, tamper-evident, easily removable seal is critical to its success. While no other processing or equipment, other than an induction sealing machine, is required to adhere the induction seal liner, there are several key process conditions that must be met and maintained throughout the filling operation to guarantee successful container sealing on a fast-moving filling line.

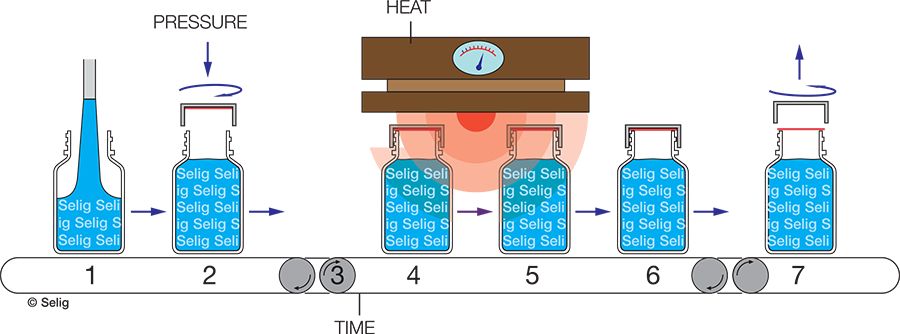

Induction heat sealing is a non-contact method involving close control of three key parameters: pressure, heat and time.

Pressure is needed for the liner to have an even seal to the lip of the container opening and is essentially achieved by the torque heads of the capper when placing the closure onto the filled container; the heads must be set up correctly to ensure that each closure is level and screwed down to the correct pressure.

Heat is subsequently applied via electromagnetic induction coils. These create a magnetic field around the foil seal, inducing an electrical current; this raises the temperature of the aluminum foil liner sufficient to melt a thin polymer layer between the foil and the neck of the closure.

Timing is crucial for a successful seal. Timing intervals include the period the closure passes beneath the induction coil and the following cooling period. The induction seal liner needs sufficient dwell time under the coil to be heated to the correct temperature for the polymer sealing surface to melt and subsequently bond to the rim of the container. Achieving a satisfactory bond between the seal and the rim of the container is determined by the cooling time interval, as the bond can only develop properly upon cooling.

Once these process parameters have been established for a given line speed, modern induction heat sealing equipment, coupled with the use of well-engineered liners such as Lift ‘n’ Peel™, will ensure consistent and accurate results.

It should be noted that induction heat sealing is not just for the big producers and packers; start-ups and smaller scale enterprises, too, can take advantage of new semi-automatic, even hand-held induction machines, to apply state-of-the-art liners that inspire consumer confidence and loyalty.

This technology therefore provides an interesting entry- level opportunity for those producers currently using milk bags or other forms of packaging, enabling them to test the market and consumer reaction, to differentiate their offering and, ultimately, boost their profitability and environmental credentials.

Thank you for creating an account and giving us the ability to serve you more effectively and quickly.

We have sent you an email so we can verify your account.