Condiments : la puissance et le potentiel de l’emballage

Condiments and sauces can be seen on dinner tables across the globe. Although often overlooked, they can be key in adding colour, texture, taste and flavour to what is being consumed. However, the actual taste experience is often determined as much by the packaging and branding of the product as by its contents1. With packaging playing a key role in customer satisfaction and purchasing decisions2, what can manufacturers learn from consumer purchasing behaviour and how has packaging evolved to cope with the many demands now being placed on it?

Since salt and vinegar were first used to enhance the flavour of foods in ancient times, people have been hooked on condiments. From the Roman practice of crushing the innards of various fish and fermenting them in salt to create garum, to today’s brightly coloured ketchups and mustards, a flourishing industry has grown.

Since salt and vinegar were first used to enhance the flavour of foods in ancient times, people have been hooked on condiments. From the Roman practice of crushing the innards of various fish and fermenting them in salt to create garum, to today’s brightly coloured ketchups and mustards, a flourishing industry has grown.

A brief walk through any food store shows just how popular condiments have become over the years. Much time and investment is given to attracting the attention of shoppers in the condiments aisle and keeping them coming back for more. Despite its significant size, the global condiments market is projected to continue to expand, reaching USD 98.3 billion by 2024 and growing at a significant CAGR of 5.4% during the forecast period, 2019–2024.3

With competition fierce for shelf space, condiments producers have had to get ever-more creative in how they attract shoppers to their products. Here are some of the ways that psychology plays a part in condiments packaging design.

Capturing consumer attention:

The popularity of condiments rises and falls. Here are the top 5 condiments in the UK and top 6 in the US at the moment.

Even since the introduction of the octagonal glass Heinz ketchup bottle in 1889, packaging has played an important role in the marketing of condiment products. Although most condiments were originally packaged in glass, consumer convenience and the cost of transporting and storing heavy items have driven the growth of PET/HDPE bottles.

Squeezable condiment pouches have also begun to make an appearance. This is because they are light to transport and easy to use. Although in the present climate, the fact that they are single-use might impact their popularity. As well as convenience, consumer demographics are also driving continued change in condiment design, with the rise in single-person households increasing demand for smaller pack sizes.

The benefits of glass for condiment packaging:

The benefits of glass for condiment packaging:

The benefits of HDPE and PET plastic for condiment packaging:

Originally most condiments were packaged in glass. The shift over recent years to plastic packaging has occurred due to the fact that it is cheaper than glass to produce and transport and offers customer convenience.

It wasn’t until the early 2000’s that the plastic bottle was turned on its head and a dispensing cap incorporated into its design. In fact, makers of Hunts’ and Heinz ketchup had to educate customers on the benefits of an inverted bottle when the new packaging was launched to US consumers in 2002. The container’s banner featured the strapline: ‘Easy Squeeze! Stay Clean Cap with Squeeze Control.”

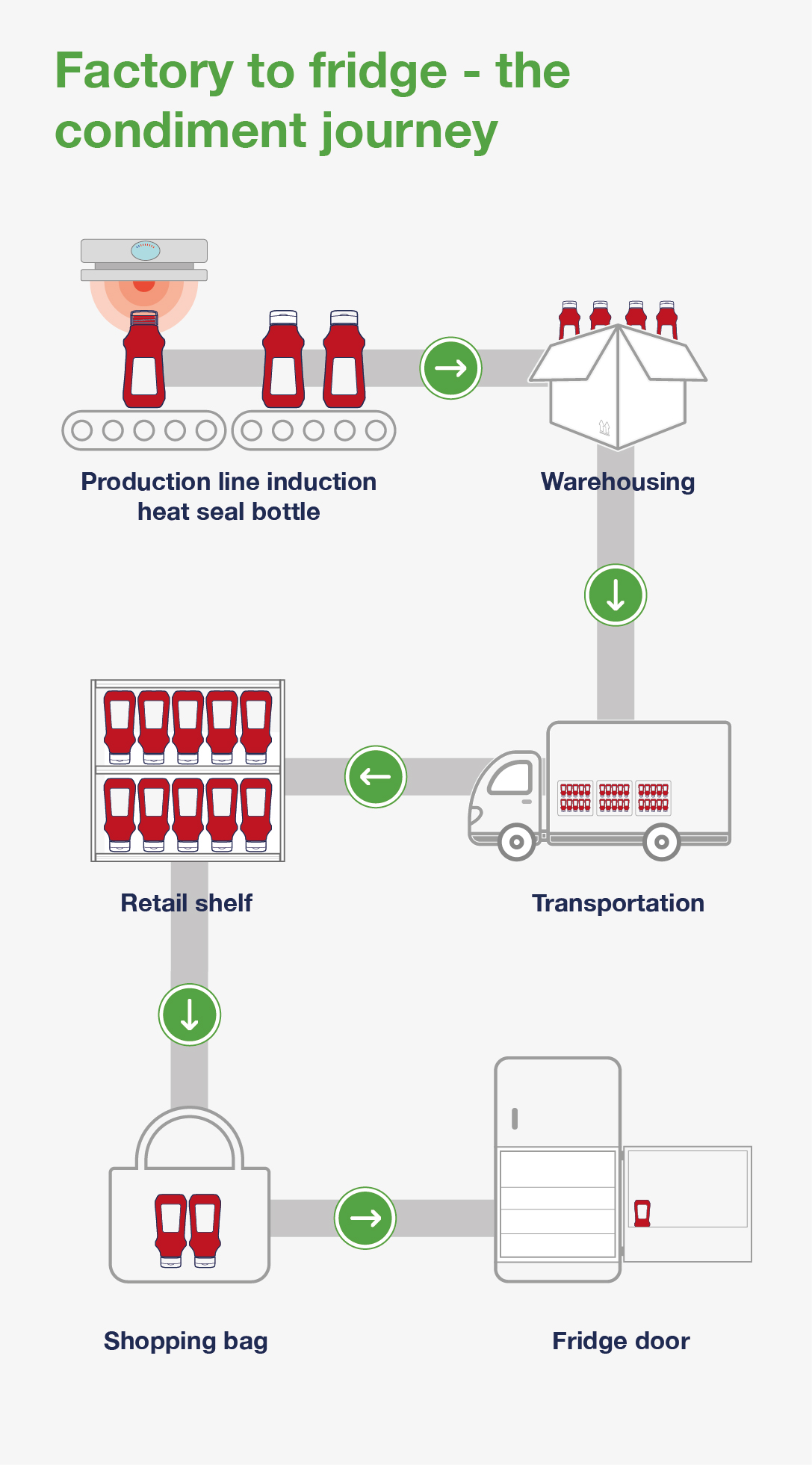

Although highly convenient for consumers, the inversion of condiments did present product integrity issues for producers. This is where a match made in heaven was formed – the plastic condiment bottle and the induction heat seal. As well as enabling a hermetic seal when the bottle is inverted, induction heat sealing also allows the plastic container to be light-weighted. This is of particular importance as producers seek to show improve their sustainability credentials.

Induction sealing is a non-contact heating process. It works by attaching a liner seal material to the bottle neck of a container. As well as enabling the creation of a hermetic seal, induction heat sealing requires little, if any, modification to a producer’s existing packaging line and promotes the product’s shelf-life by protecting against moisture and oxygen ingress.

While leakage prevention is often the primary driver for the adoption of induction foil seals in condiments packaging, there are other benefits to consider as well:

While leakage prevention is often the primary driver for the adoption of induction foil seals in condiments packaging, there are other benefits to consider as well:

As a global leader in induction sealing solutions, Selig has helped many producers resolve their condiment packaging seal challenges. Thanks to induction heat sealing, both plastic and glass condiment bottles and jars containing oily and non-oily foods alike can be sealed securely, with no leakage.

Although only a small part of the condiment packaging mix, the induction heat seal brings peace of mind to many manufacturers, so why not see if Selig can help you improve seal integrity, extend shelf-life and keep your customers happy too?

Merci de créer un compte et de nous donner la possibilité de vous servir plus efficacement et plus rapidement.

Nous vous avons envoyé un e-mail pour que nous puissions vérifier votre compte.