Envasado flexible – El panorama cambiante

We might be forgiven for thinking that flexible packaging is a relatively new concept. However, as far back as the second Century BC, when the Chinese used the bark of the mulberry tree to wrap their food1, flexible packaging has been used to protect and preserve fragile goods. Although plastic was discovered in the 19th Century, it wasn’t until the 20th Century that its potential as a packaging material began to be explored.

Now, packaging is the largest end-user segment for plastic products, accounting for more than 40% of the total plastic usage in the world2. Within this category, flexible plastic packaging is used to protect many products. It is such a versatile packaging solution that the flexible packaging market was valued at USD 230.49 billion in 2020, and it is projected to be worth USD 289.89 billion by 2026, registering a CAGR of 3.89% during the forecast period (2021 – 2026)3.

The reasons for flexible packaging’s popularity are numerous. As a material it is lightweight, durable, cost-effective, and convenient. It also offers producers on-pack design opportunities, cheaper transportation and shelf-life supply chain benefits, as well as consumer health and safety reassurance. However, things are changing for flexible packaging. Some of the main drivers include concern for the environment, the changing face of convenience and technological advances.

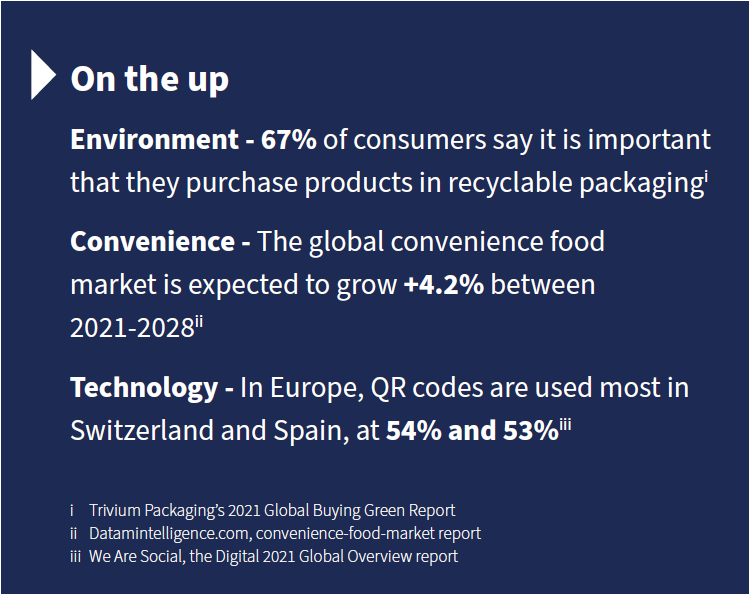

Increasing concern for the environment – sustainability is now top of consumer concerns when it comes to packaging. With single-use, plastic-based flexible packaging firmly on the consumer watch-list, producers are increasingly having to look at incorporating more recyclable content into their flexible packaging and explore more sustainable biodegradable, compostable, returnable or recyclable solutions.

Convenience drives packaging changes – demand for more convenience is driving design changes in flexible packaging. As a result, pouch packaging and sharing packs are increasing in popularity. As well as being lightweight and an economical way to package specifically tailored servings for snack products, pet foods Etc., the additional ability to add zipped closures makes them appealing single-serve and sharing serving solutions.

Technology augments consumer experience – one of the by-products of the pandemic has been a wider consumer acceptance for scanning QR codes. This, amongst other technologies, is now being used to full effect on flexible packaging to augment the consumer experience. From website to video QR codes, the ability to drive customers to more information about the product is a powerful one that is being experienced by a wider consumer demographic than ever before.

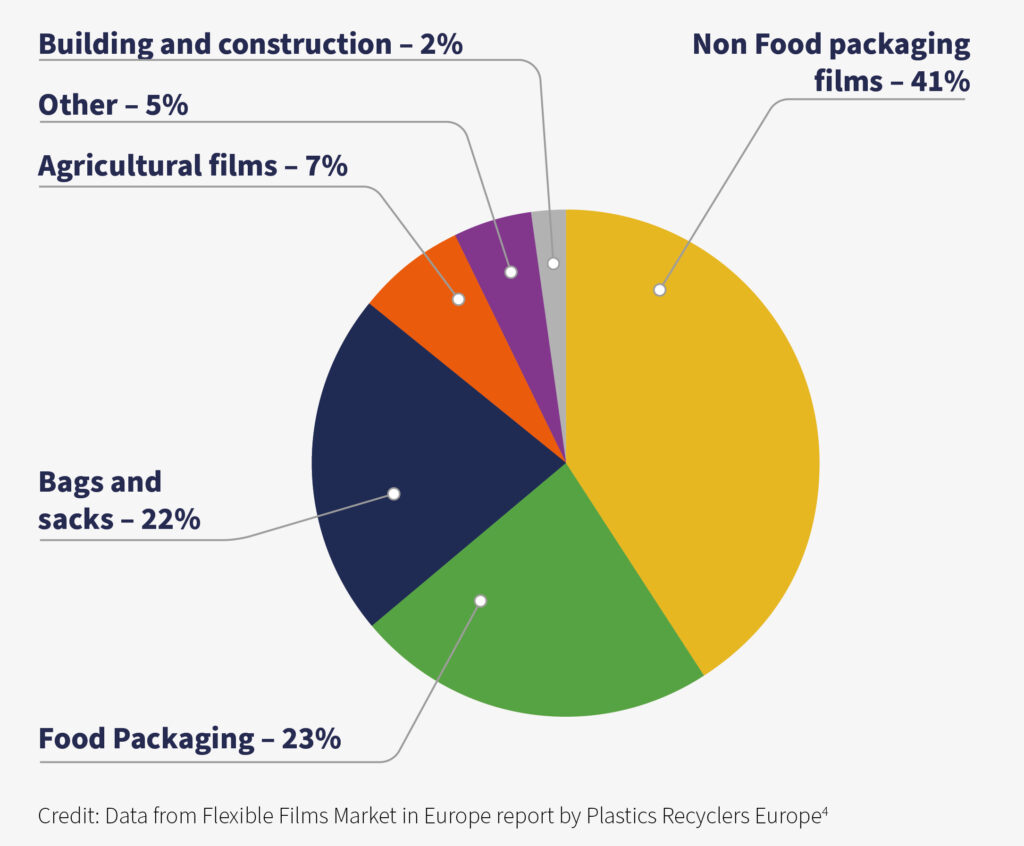

Demand for polyethylene (PE) flexible films is on the rise and is coming from a number of different sectors – including a sizeable share of food packaging producers.

Consumers across the globe want more recyclable packaging. According to those surveyed in the US, Europe, and South America, two out of every three see environmentally friendly, recyclable packaging as important and 74% would pay more for sustainable packaging5.

Consumers across the globe want more recyclable packaging. According to those surveyed in the US, Europe, and South America, two out of every three see environmentally friendly, recyclable packaging as important and 74% would pay more for sustainable packaging5.

At present, there are many different grades of PE used in food packaging and the challenge for many producers is that flexible plastic packaging recycling rates vary depending on the country and even region that recycling schemes are operating in. At present, flexible plastic packaging recycling rates are relatively low.

Recycling rates of plastic packaging waste (including rigid and flexible plastics) in Europe vary significantly, ranging from 26% to 52%6. However, with the introduction of The Directive (EU) 2019/852 on Packaging and Packaging Waste, higher recycling targets per material have been set (50% for plastic packaging by 2025 and 55% by 2030), and a new calculation method of recycling performances has been put in place.

The reason for low recycling rates across many countries can be broadly explained by widespread consumer confusion as to what can and can’t be recycled, multi-layer materials that can’t yet be recycled and limited recycling infrastructures in some regions.

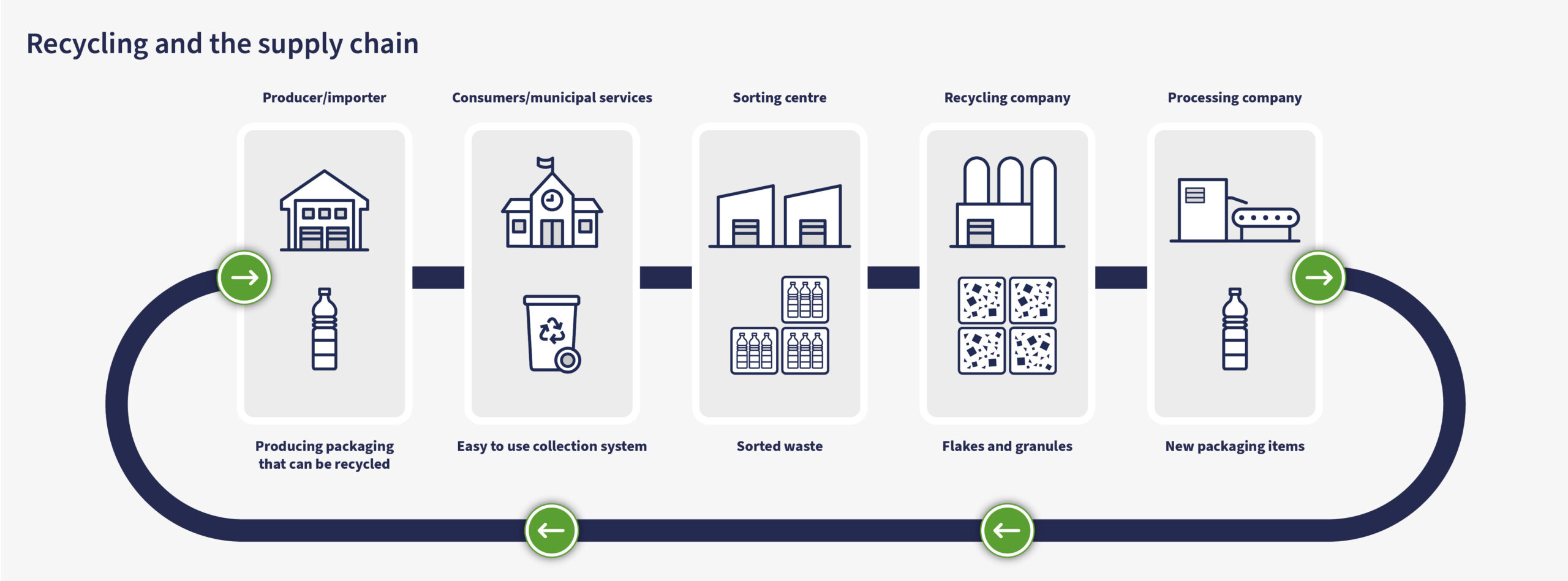

According to the European Commission’s New Circular Economy Action Plan7 design is key to sustainability; with up to 80% of a product’s environmental impact determined at the design phase8 and one of the barriers to the expansion of markets for circular products being the complexity of packaging materials. However, transitioning from a linear economy that sees plastic packaging as disposable to a fully circular one needs more than just re-designed packaging, it needs a cohesive recycling strategy that involves many players.

So, how can producers play their part in giving consumers what they want, whilst still delivering light weight packaging that promotes health and safety, is durable and convenient, has graphic impact, can be designed to very specific requirements and offer supply chain benefits?

Building more sustainability into flexible packaging, without compromising material performance, is being approached in several ways at present by producers:

Building more sustainability into flexible packaging, without compromising material performance, is being approached in several ways at present by producers:

As well as continued consumer education, waste collection and materials recyclability need to be developed in parallel. However, with consumers demanding change, how is the flexible packaging used on your product lines being altered to meet this need?

A case in point

With the focus squarely on plastic packaging waste reduction, Selig Flexibles is working with clients to offer them more biodegradable and recyclable flexible packaging solutions. The company’s 84% recyclable flexible plastic packaging is being trialled in companies across Europe at present and has recently been approved for use by a German baby food manufacturer seeking to improve its sustainability credentials.

As the degree of a flexible film’s recyclability is impacted by the type of method used to seal the product and the inks featuring on the packaging’s surface, further trials are underway by Selig Flexibles to achieve recyclability of more than 90%. These will subsequently be certified by RecyClass, to achieve Recycled Content Certification.

As flexible packaging requirements change, getting the right partner has become even more important. And as a customer focused producer, Selig Flexibles offers a customised service, low minimum order quantities and short lead times – for both cold and hot seal packaging.

Gracias por crear una cuenta y darnos la posibilidad de atenderle de una forma más eficiente y con mayor rapidez.

Le hemos enviado un correo electrónico para verificar su cuenta.